Edwards: iXL 120 | 2009

The iXL 120 dry-pump by Edwards Limited was developed over a two year period. The project was centrally managed but the elements of the pump were split down to several different design teams across different UK sites. The Edwards site in Eastbourne develops all aspects of pump controls - both the software and hardware - in house using multi disciplinary teams.

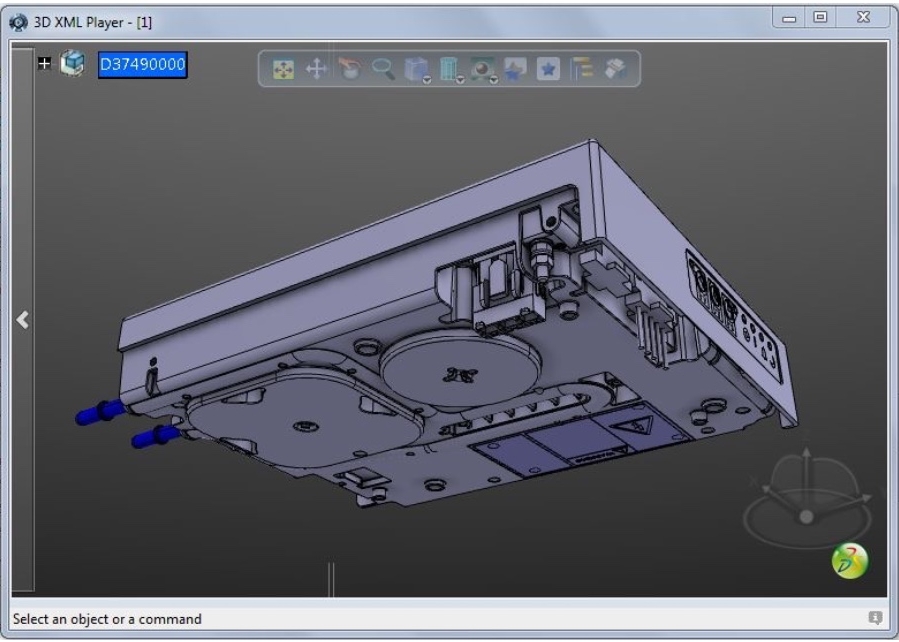

The ‘drive unit’ and ‘controller unit’ for the iXL 120 pump were developed in conjunction with the design team based in Shoreham developing the pump internals.

The drive unit (on top of the pump) comprised three main elements: a polymer cover with a drive interface, a water-cooled die-cast base & a PCB containing all the power electronics.

The whole drive unit casting was designed and rigorously tested as a sand-cast part prior to being tooled as a die-casting.

The less visible (but equally vital) control unit was located inside the rear of the pump housing and required complex shaping to make use of the limited space left inside the pump body.

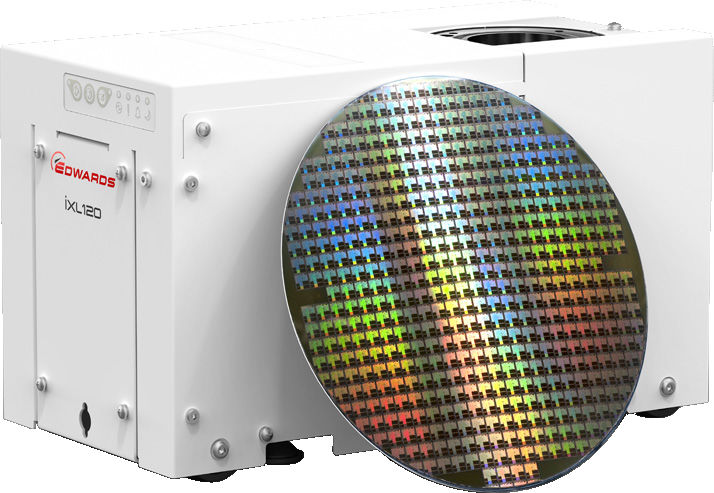

As industrial products these pumps are largely unseen in the sub-basement areas in wafer fabs making semi conductor wafers. Nevertheless Edwards places a high value on the product design used in the manufacture of their products.

The iXL 120 with a semi-con wafer

The underside of the water-cooled iXL 120 drive