Soil Pro | 2023

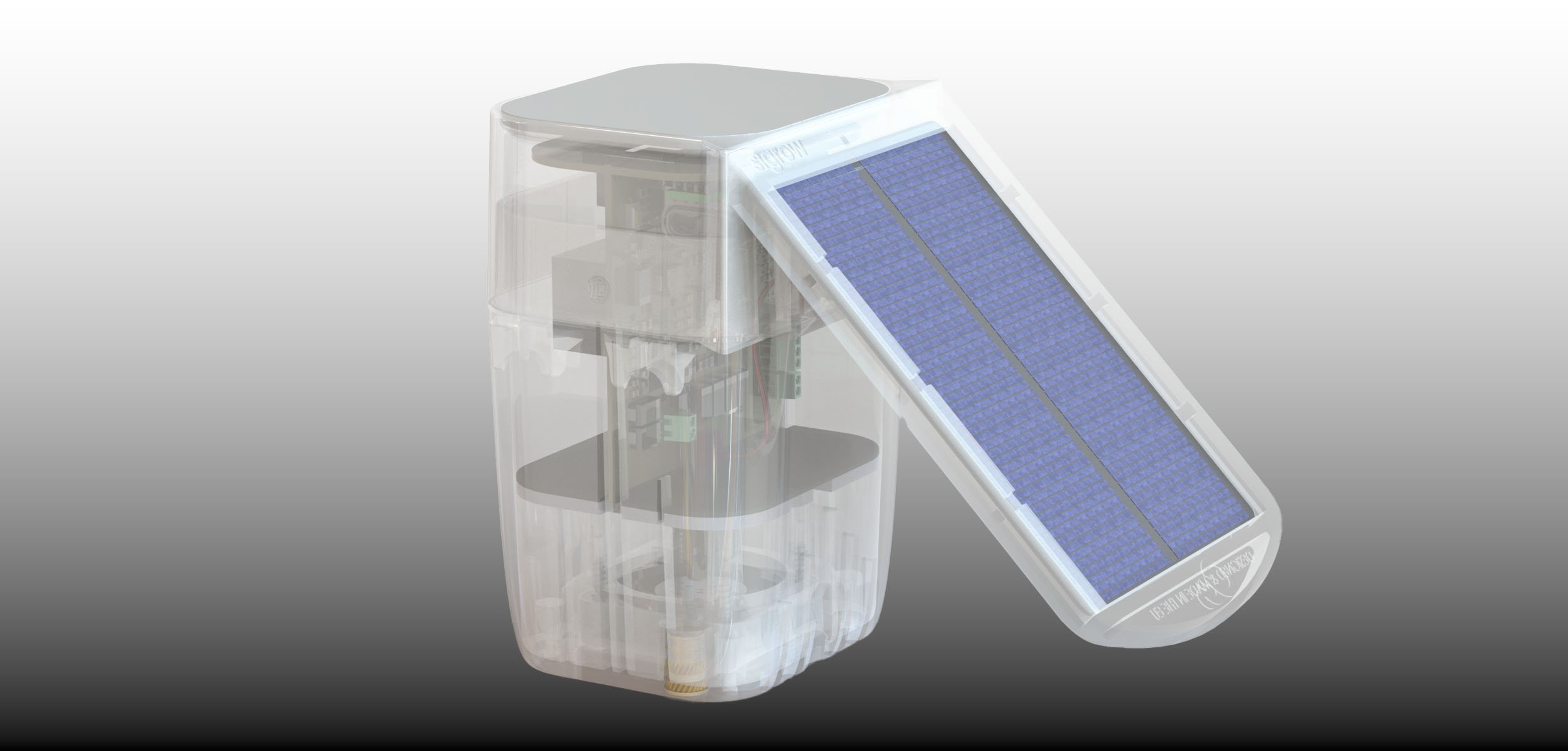

Design, DFM, Prototyping to Injection Moulding

This project was an evolution of an existing product made in smaller volumes through 3D printing. Having proven & refined the technology it was now time to scale to the bigger volumes offered by injection moulding. Using the 3D printed hardware as a starting point it provided the opportunity to redesign to product specifically for injection molding. The new design allowed for changes to improve assembly and include other features within the design. Once again, like on the CNV5, a close collaboration with the clients PCBA designer ensured the new design met the client requirements.

All three main components are moulded in a single open-shut tool from >ASA+PC< polymer and the final assembly is done in the Netherlands.

The design utilises a large solar panel to trickle charge the on board batteries.

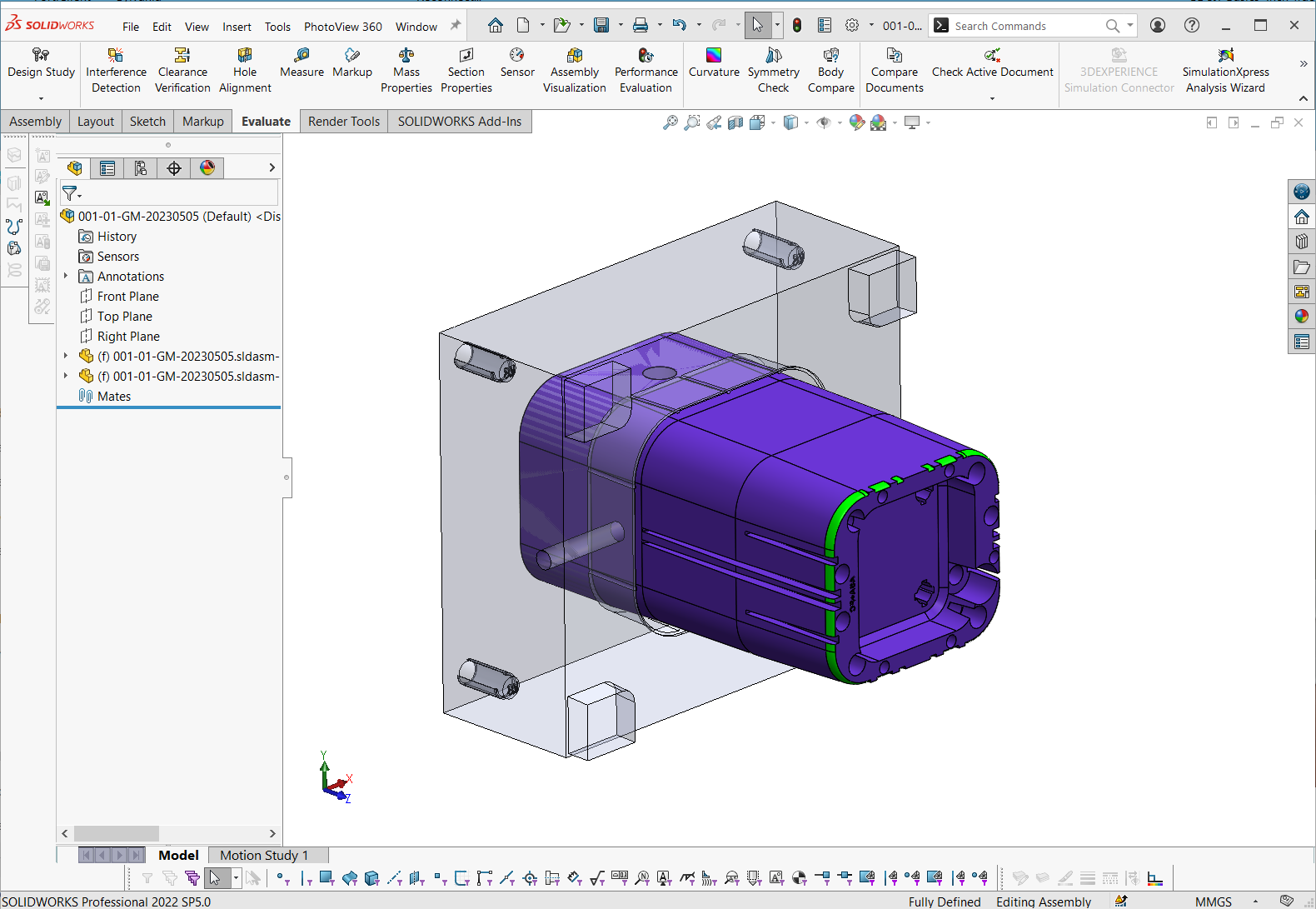

Clash analysis was done on SolidWorks to ensure no issues for assembly.

CAD renderings allowed for pre-launch marketing material to be created

Design reviews with the tool maker.

Soil Pro installed on site in the Netherlands

Apart from the screws fixing the fan there are no other fasteners.

Successful T1 first off parts from the injection moulding tool.